Electrode induction aerosolization(EIGA)

Vacuum smelting gas atomization powder making equipment (EIGA) is a process for preparing spherical powder from pure metal or alloy wire, and a process for preparing spherical powder from pure metal or alloy wire, mainly used for the preparation of pure titanium and titanium alloys, nickel-based alloys, nitinol shape memory alloys and other powders, powder products are widely used in additive manufacturing (3D printing), powder metallurgy, hot isostatic pressing, injection molding and other manufacturing processes.

I.Equipment advantages

1.Excellent applicability can prepare a variety of alloy metal powder, typical products are stainless steel, die steel, high temperature alloys, cobalt-chromium alloy, aluminium alloy and so on.

2.Variety of furnace feeds variety of furnace feeds, choice of alloying ingredients, master alloys, powder return materials.

3.Cold speed cold speed, droplet cooling solidification rate of 103 ~ 106K / s, rapid solidification for fine microcrystalline organisation.

4.Vacuum refining refining alloy under vacuum, high purity of powder, low gas and impurity content.

5.Good powder quality using tightly coupled aerosol nozzle technology, good powder quality, high sphericity and controllable particle size.

6.Mature process mature process, easy operation, short production lead time, stable mass production.

II.Device parameters

| performance parameter | EIGA50/500 | EIGA70/1000 | EIGA100/1200 |

| Electrode size (mm * mm) | 50*700 | 70*1000 | 100*1200 |

| Loading capacity (TC4. KG) | 6 | 17.3 | 42 |

| Melting power (kw) | 60 | 120 | 150 |

| Melting speed (kg * min) | 0.5 | 1.5 | 2.5 |

| Atomization time (min) | 10 | 20 | 30 |

| Total cycle time (min) | 15 | 25 | 35 |

| Maximum annual powder production (mt/y) | 150 | 220 | 330 |

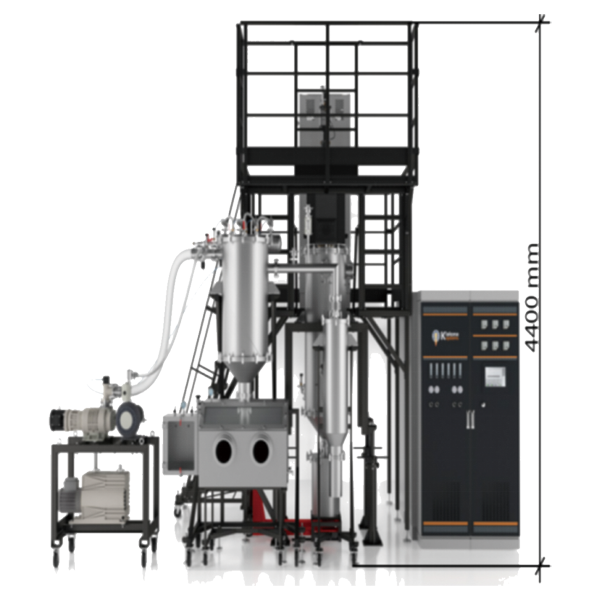

Vacuum Melting Gas Atomization Milling Equipment (VIGA)

Vacuum smelting gas atomization powder making equipment (VIGA) is mainly used for the preparation of high-performance iron-based, nickel-based, cobalt-based, aluminum-based, copper-based and other advanced metal and alloy powder materials, and the material products are suitable for additive manufacturing (3D printing), melt deposition, laser cladding, thermal spraying, powder metallurgy, hot isostatic pressing and other advanced manufacturing processes, which are widely used in aerospace, biomedical, tools, automobiles, machinery, electronics, new energy and other fields. It has the characteristics of low air consumption, low empty heart rate, high sphericity, high fine powder rate, and high purity

I.Equipment advantages

1.Excellent applicability can prepare a variety of alloy metal powder, typical products are stainless steel, die steel, high temperature alloys, cobalt-chromium alloy, aluminium alloy and so on.

2.Variety of furnace feeds variety of furnace feeds, choice of alloying ingredients, master alloys, powder return materials

3.Cold speed cold speed, droplet cooling solidification rate of 103 ~ 106K / s, rapid solidification for fine microcrystalline organisation

4.Vacuum refining refining alloy under vacuum, high purity of powder, low gas and impurity content

5.Good powder quality using tightly coupled aerosol nozzle technology, good powder quality, high sphericity and controllable particle size.

6.Mature process mature process, easy operation, short production lead time, stable mass production

II.Device parameters

| performance parameter | VIGA01 | VIGA10 | VIGA20 | VIGA50 | VIGA100 | VIGA250 | VIGA300 | VIGA500 |

| maximum height | 3.2 | 4.7 | 6.7 | 7 | 9.5 | 11.5 | 12.5 | 13.5 |

| cover an area | 3*3 | 5*6 | 6*7 | 6.5*7.5 | 7*8 | 8*9 | 8*9 | 10*12 |

| Maximum weight per batch | 1 | 10 | 20 | 50 | 100 | 250 | 300 | 500 |

| Metal flow rate (kg/min) | 1-5 | 3-10 | 5-15 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

| Atomized gas flow rate (m3/h) | 300-400 | 300-600 | 400-700 | 800-1000 | 800-1200 | 800-1200 | 800-1200 | 800-1200 |

| Atomization time (min) | 2 | 4-8 | 5-15 | 10-20 | 10-30 | 15-40 | 30-50 | 40-70 |

| Maximum annual powder production (mt/y) | 5 | 15 | 30 | 60 | 200 | 400 | 600 | 960 |

| D50 value range (um) | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 | 20-120 |

RF induction plasma technology

The equipment is mainly used for the preparation of nickel-based superalloy powder, titanium alloy powder, stainless steel powder and refractory metal powder, etc., the powder products have excellent comprehensive performance, and are widely used in additive manufacturing (3D printing), thermal spraying, powder metallurgy, hot isostatic pressing and other manufacturing processes.

I.Equipment advantages

1.Good quality of milling The surface of the prepared powder particles is smooth and clean, with few gas inclusions and excellent overall performance.

2.Highly automated Simple control of process parameters, easy to operate, can be automated production.

3.Excellent applicability Preparation of Ti, Ni, Co refractory metals and alloys, high applicability of powder making.

4.Mature technology Mature process technology, can be small batch trial production or continuous large quantities of stable production.

II.Device parameters

| product type | Tungsten, titanium, refractory metals |

| Purification factor | 10 times |

| Density factor | 3 times |

| nodularity | ≈95% |

| Powder refractory point | unlimited |

| Types of raw materials | Crushed state, sponge state, fiber state, atomized liquid state |

| production | ≥4kg/h |

| Powder has gone through | 0-200um |

| Sphericity | ≥95% |

| 15-53um yield | Titanium alloy ≥ 85%, tungsten ≥ 95% |

| melting temperature | 3000°-10000° |

| application area | Powder metallurgy, additive manufacturing |

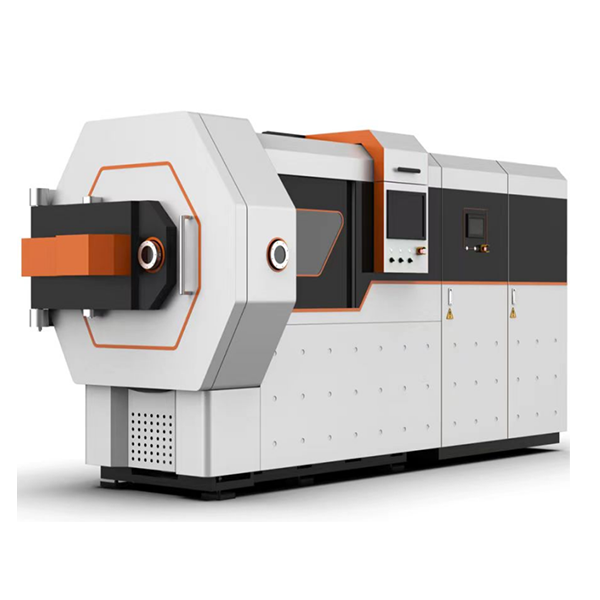

Plasma Rotating Electrode Atomization Equipment (PREP)

It is a process for preparing spherical powder using pure metal or alloy wire as raw materials. It is mainly used to prepare powders such as pure titanium and titanium alloys, nickel-based alloys, nickel-titanium shape memory alloys, etc. Powder products are widely used in additive manufacturing (3D printing), powder metallurgy, hot isostatic pressing, injection molding and other manufacturing process fields.

I.Equipment advantages

1.Good quality of powder making The surface of the prepared powder particles is smooth and clean, with few gas inclusions and excellent overall performance.

2.Highly automated Simple control of process parameters, easy to operate, can be automated production

3.Excellent applicability Preparation of Ti, Ni, Co refractory metals and alloys, high applicability of powder making.

4.Mature technology Mature process technology, can be small batch trial production or continuous large quantities of stable production

5.Low overall energy consumption Low gas consumption, low overall energy consumption

II.Device parameters

| product type | Titanium alloy, high-temperature alloy, refractory alloy |

| Maximum speed | 60000r/min |

| powder particle size | 10-200um |

| Powder sphericity | ≥95% |

| application area | Powder metallurgy, additive manufacturing |

Plasma wire atomization equipment (PA)

It is a process for preparing spherical powder using pure metal or alloy wire as raw materials. It is mainly used to prepare powders such as pure titanium and titanium alloys, nickel-based alloys, nickel-titanium shape memory alloys, etc. Powder products are widely used in additive manufacturing (3D printing), powder metallurgy, hot isostatic pressing, injection molding and other manufacturing process fields.

I.Equipment advantages

1.Non-contact :melting The melting process is non-contact melting, no introduction of impurities, high purity of powder.

2.Low overall :energy consumption Low gas consumption, low overall energy consumption

3.Cooling speed :Cooling rate reaches 103~106K/s, rapid solidification to fine microcrystalline organisation

4.Good quality of powder: making Powder with high sphericity, few satellite particles, good flowability

5.Manufacture of multi-alloyed materials :Preparation of reactive or refractory metals such as Ti, Zr, Mo, Nb, Ta, W and their alloy powders.

II.Device parameters

| product type | Titanium alloy, high-temperature alloy, refractory alloy |

| Design annual production capacity | 50T |

| Physical and chemical efficiency | 8KG/H |

| 15-53um yield | ≥55% |

| application area | Aerospace, Medical, Chemical |

Introduction to the principle of ultrasonic atomization pulverizer

Surface vibration with ultrasonic frequency and metal solution wetting the surface, the molten liquid spreads into a liquid film under the action of ultrasonic vibration. When the amplitude of the vibration surface reaches a certain value, it is shattered under the action of ultrasonic vibration, and the excited droplets fly out of the vibration surface to form mist droplets.

I.Equipment advantages

1.Variety of furnace feeds :variety of furnace feeds, choice of alloying ingredients, master alloys, powder return materials

2.Low overall energy consumption: Low gas consumption, low overall energy consumption

3.Cold speed :cold speed, droplet cooling solidification rate of 103 ~ 106K / s, rapid solidification for fine microcrystalline organisation

4.Good powder quality :using tightly coupled aerosol nozzle technology, good powder quality, high sphericity and controllable particle size.

5.Manufacture of multi-alloyed materials :Preparation of reactive or refractory metals such as Ti, Zr, Mo and their alloy powders.

6.Mature process: mature process, easy operation, short production lead time, stable mass production

II.Device parameters

| Melting method | induction melting |

| Applicable materials | The melting point of metals is around 1300 ° C, and volatile materials such as Sn are relatively low and easy to evaporate in plasma, Zn, Mg, Pb, and AI |

| material form | unlimited |

| Types of raw materials | Crushed state, sponge state, fiber state, atomized liquid state |

| Powder has gone through | 0-200um |

| application area | Powder metallurgy, additive manufacturing |

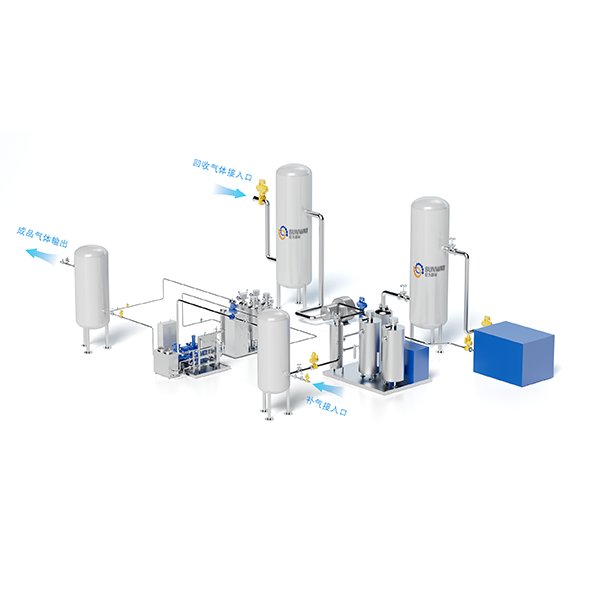

Argon gas recovery

I.Equipment advantages

1.Precision filtration :Complete filtration system, high precision filtration of dust and other media.

2.High overall recovery rate: Overall recovery of up to 99 per cent through precision filtration and two-stage pressure regulation.

3.High degree of automation :The whole process is automated, saving manpower costs and reducing labour intensity.

4.Low overall energy consumption :Low gas consumption, low overall energy consumption

II.Device parameters

| Main configuration | quantity | notes |

| Inlet dust filtration system | 1 set | Filter fine dust in the system with a filtration accuracy of<0.1um |

| Low pressure buffer storage tank | 1 piece | Volume 15m3, working pressure 1MPa |

| Variable frequency screw compressor | 1 unit | oil |

| Argon drying system | 1 group | Drying treatment of gases |

| Argon deoxygenation system | 1 group | Purifying a small amount of oxygen in argon gas |

| Medium pressure buffer storage tank | 1 piece | Volume: 5m3, working pressure: 1.6MPa |

| Liquid driven piston compressor | 1 unit | 220KW, hydraulic driven, oil-free lubrication |

| High pressure buffer storage tank | 1 piece | Volume: 5m3, working pressure: 6.5Mpa |

| water chiller | 1 unit | Used for cooling the system |

| medium | argon | Oxygen content after purification | ≤5PPM |

| internet traffic | ≥ 1500m³/h | Oil content | ≤0.01ppm |

| Initial pressure of recovered gas | 0.010-0.015Mpa | Dew point temperature | ≤-65°C |

| Pressure after pressurization | ≥6MPa | Media filtration accuracy | <0.1um |

| Overall recycling rate | ≥99% | Total power of equipment | 470KW |

Printing powder automatic processing line

The equipment uses high-frequency ultrasonic technology to atomize the molten metal into high-sphericity, low-oxygen content powder under the protection of inert gas, realizing intelligent control of the entire process from powder preparation to management, and can accurately supply powder to the printer.

I.Equipment advantages

1.Precision replenishment: Precise supply of powder to the printer in the form of a pipeline.

2.Improved powder utilisation Through the form of negative pressure pipeline transport, the powder will be transported and inhaled to the screening station to remove impurities and then automatically backfill the printer buffer bin.

3.High degree of automation The whole process is automated, saving manpower costs, reducing human labour costs and protected by inert gas

4.Avoiding oxidation Protected by inert gas to avoid oxidation caused by the powder running process

II.Device parameters

| capacity | >150KG |

| meshes | 100-635 |

| voltage | 380V 50HZ |

| power | 10kw |

| Gas consumption of argon gas | 50Nm³/H |

| Compressed air consumption | 18Nm³/H |

| Oxygenation control | ≤20PPM |

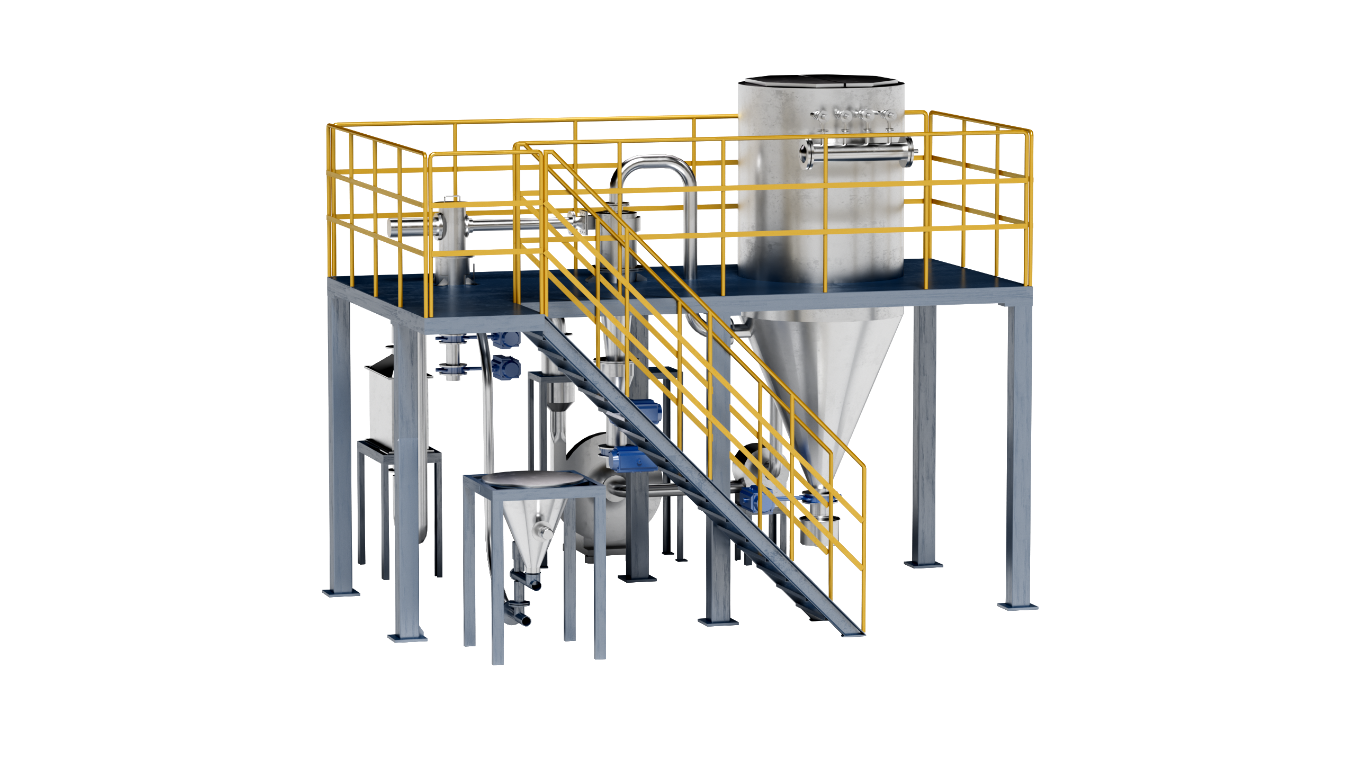

Multi functional powder post-processing automatic production line

The equipment integrates advanced automated conveying, uniform feeding screening, grading, mixing and packaging information management functions, realizing integrated and continuous operation from raw materials to finished products, and a fully enclosed and automated powder transfer process to avoid oxidation caused by the environment during powder transfer.

I.Equipment advantages

1.Fully automated hermetic operation: Avoids oxidation caused by the environment during powder operation.

2.High precision powder screening :High screening accuracy and perfect grading system.

3.High degree of automation :The whole process is automated, saving manpower costs and reducing labour intensity.

4.Low overall energy consumption: Low gas consumption, low overall energy consumption.

5.Oxygen free packaging :The whole production is carried out in an oxygen-free closed environment, avoiding oxidation phenomenon.

II.Device parameters

| capacity | 150-200KG |

| meshes | one hundred point two seven zero |

| voltage | 380V 50HZ |

| power | 55kw |

| Gas consumption of argon gas | 40Nm³/H |

| Compressed air consumption | 24Nm³/H |

| Oxygenation control | ≤120PPM |

| Packaging specifications | customizable |

| Suitable for preparing powder furnace | Aerosolization equipment, centrifugal atomization equipment |

| installation height | 6M |

| cover an area | 7.6M*3M |

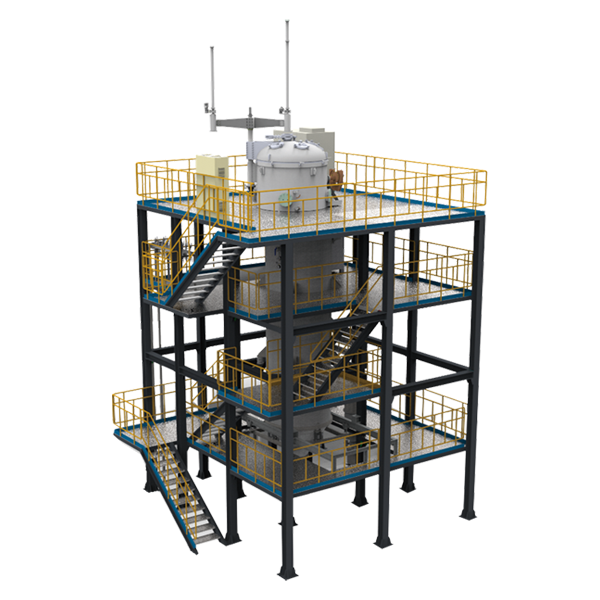

Vertical powder post-processing automatic production line

The production line integrates intelligent control and efficient processing technology, aiming to improve the efficiency and safety of the entire process of metal powder post-processing. Its core equipment adopts a vertical design, combined with automated screening, mixing, grading and packaging systems, which significantly reduces manual intervention and optimizes resource utilization.

I.Equipment advantages

1.Fully automated hermetic operation :Avoids oxidation caused by the environment during powder operation.

2.High precision powder screening :High screening accuracy and perfect grading system.

3.High degree of automation :The whole process is automated, saving manpower costs and reducing labour intensity.

4.Low overall energy consumption :Low gas consumption, low overall energy consumption.

5.Oxygen free packaging :The whole production is carried out in an oxygen-free closed environment, avoiding oxidation phenomenon

II.Device parameters

| capacity | 150-200KG |

| meshes | one hundred point two seven zero |

| voltage | 380V 50HZ |

| power | 37kw |

| Gas consumption of argon gas | 20Nm³/H |

| Compressed air consumption | 18Nm³/H |

| Oxygenation control | ≤120PPM |

| Packaging specifications | customizable |

| Suitable for preparing powder furnace | Aerosolization equipment, centrifugal atomization equipment |

| installation height | 11M |

| cover an area | 5M*4M |

NLUS-800-GS Square Ultrasonic Electromagnetic Screen

I.Equipment advantages

1.Highly efficient decontamination :Rapid separation of impurities in the material to ensure screening purity

2.High screening efficiency :The vibration energy generated by electromagnetic technology is used to make the powder evenly distributed on the screen.

3.High degree of automation :The whole process is automated, saving manpower costs and reducing labour intensity.

4.High screening accuracy :Ultrasonic micron-sized vibration and electromagnetic synergy control, accurate separation of different particle size particles

5.Preventing net clogging :High-frequency micro-amplitude vibration effectively disperses adherent particles, reduces clogging of screen holes and extends screen life.

II.Device parameters

| Number of sieve layers | 1st floor |

| screen area | 0.16㎡ |

| Mesh size of sieve | 100-635 mesh |

| Screening accuracy | ≥98% |

| design capacity | Stainless steel as an example ≥ 150KG/H |

| electromagnetic power | 220V50HZ/60HZ 220W |

| ultrasonic power | 220V50HZ/60HZ 0.1KW |

| Gas protection pressure | 0.05Mpa |

Airflow classification equipment

I.Equipment advantages

1.Continuous feed :Continuous feeding, uninterrupted production, suitable for all kinds of metal powder.

2.Modularisation:Compact design and high degree of modularity,adapt to multiple scenarios, easy to maintain and with low expansion costs.

3.High degree of automation :The whole process is automated, saving manpower costs and reducing labour intensity.

4.Precise separation :Precise separation of the corresponding material zones.

II.Device parameters

| capacity | 30-200KG |

| Separate particle size | 3-200um |

| accuracy | ±1um |

| Gas medium | Nitrogen, argon |

| Oxygenation control | ≤60PPM |

| Grading order | Maximum 3 levels |

| Gas consumption | Please refer to the specific model data |

| application area | Powder post-treatment, powder shaping |

NMSU16-S4-NX-EX anaerobic mini sieve

I.Equipment advantages

1.Highly efficient decontamination :Ultrasonic and electromagnetic synergy, rapid separation of impurities, to ensure high purity of materials.

2.Preventing net clogging :High-frequency vibration combined with ultrasonic screen cleaning to avoid particle adhesion and clogging.

3.Lightweight construction :Compact and modular design, easy to move and install, flexible to adapt to the laboratory or small production line.

4.Good appearance :Industrial-grade simple shape, material texture delicate, both practical and equipment visual presentation.

5.Ultrasonic cleaner :Ultrasonic automatic sieve hole cleaning, reducing manual intervention.

6.High efficiency: Dual power drives optimise screen speeds and shorten cycle times.

II.Device parameters

| Number of sieve layers | 1st floor |

| screen area | 0.125㎡ |

| Mesh size of sieve | 100-635 mesh |

| Screening accuracy | ≥98% |

| design capacity | Stainless steel as an example ≥ 150KG/H |

| electromagnetic power | 220V50HZ/60HZ 100W |

| ultrasonic power | 220V50HZ/60HZ 0.1KW |

| Gas protection pressure | 0.05Mpa |

NHIU40B-S6C-NX-EX anaerobic ultrasonic screening machine

I.Equipment advantages

1.High screening accuracy Ultrasonic technology accurately regulates the vibration of the sieve holes to achieve micron-sized particle classification.

2.Fruitful Optimisation of screen surface area and amplitude parameters, 40% increase in throughput per unit of time.

3.Good sealing Totally enclosed structure combined with multi-layer sealing design to prevent dust leakage.

4.Excellent gas protection Built-in inert gas circulation system, effectively isolating oxygen.

5.Easy to disassemble and clean Modular components and quick release interface design, simplify the maintenance process.

II.Device parameters

| Number of sieve layers | Floors 1-3 |

| screen area | 0.28-1.13㎡xN |

| Mesh size of sieve | 0-800 mesh |

| Screening accuracy | >95% |

| design capacity | Taking 1200 type as an example,>100KG/H |

| ultrasonic power | 220V50HZ/60HZ100W |

| Oxygen increment | Less than 50ppm |

| configuration | Explosion proof screen mesh, diamond screen mesh |