Click on the device image to jump to the corresponding parameters

We have Screening equipment for the whole industry

The product line with screening technology as the core covers a complete set of solutions for filtration, transportation, dust removal, accurate feeding, laboratory, etc.

Micron level screening technology

Complete solution

Feeding and conveying

Industry-wide solutions

The purpose of our equipment.

We know our core strengths, stick to our guns and hone our skills. Most Importantly, we stay focused.

Classification and impurity removal

Conventional screening from nanometer to millimeter level

Conveying and loading

Complete design plan for powder factory

Packaging and weighing

Ton bag unpacking and sealing related equipment

Whole screening and conveying scheme

Industry-wide equipment provider

Process support.

Our screening equipment can be used in the following industries

powder

coating

Chemical industry

Medical beauty

food

experiment

Abrasive

Screening Equipment.

Hot selling devices

NHFF series high frequency screen.

The NHFF series high-frequency screen was originally designed to meet the special process required by Navigat to filter BYD’s viscous battery material slurry. Because of its excellent efficiency and special performance, it has become the first choice for the slurry and slurry produced in other industries. It also performs well in material filtration applications.

Materials that are lightweight, prone to agglomeration, and have a low melting point

| Power supply: | 380 ± 10% AC 50Hz |

| Working air pressure: | 0.2MPa-0.4MPa |

| Environmental temperature: | normal temperature |

| Explosion proof requirements: | NO |

| Product: | Powder |

| Equipment noise: | Less than 70dB beyond 1 meter |

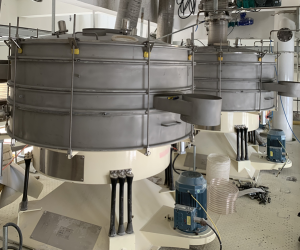

NRTS series square swing screen.

NRTS square swing screen is a high-capacity and high-performance screening equipment developed and designed to achieve high-precision and large-throughput requirements for medium and large-scale screening in production. It is used in a variety of industries and fields, proving its durability and reliability. and accuracy, with strong screening capabilities.

Multiple industries and fields

| Positive displacement stroke mm | 52 64 64 64 76 92 52 64 64 64 76 92 52 64 64 64 76 92 |

| Power(KW) | 1.5 2.2 4 5.5 7.5 1.5 2.2 4 5.5 7.5 11 11 1.5 2.2 4 5.5 7.5 11 |

| Rounds per min(r/min) | 940 960 960 940 960 960 960 960 960 960 960 960 940 960 960 960 960 960 |

| Weight(kg) | 350 960 1100 2300 3600 5000 400 1080 1230 2600 3900 5200 450 1250 1500 3200 4100 5500 |

| Model | NAFS0515 NAFS1021 NAFS1030 NAFS1530 NAFS1836 NAFS2050 NAFS0515 NAFS1021 NAFS1030 NAFS1530 NAFS1836 NAFS2050 NAFS0515 NAFS1021 NAFS1030 NAFS1530 NAFS1836 NAFS2050 |

NLS series linear vibrating screen.

The NLS series linear vibrating screen machine developed and produced by Navigat optimizes and upgrades the traditional linear screen. It can separate general materials, including effective separation of dry particles and slurry-containing materials. It has low energy consumption, high output and simple structure. , easy to maintain, fully enclosed structure, no dust spillage, automatic discharge, suitable for assembly line operations.

Dry particles, slurry materials

| Field of the application | Food,medicine,chemicals,abrasives,ceramics, mining, metallurgy,cosmetics and other industries |

| Feed size | 0.074 – 10 mm |

| Screen | Stainless steel 304/316 |

| Angle of inclination | 1°- 7° |

| No. of screen decks | 1 -2 per machine |

| Anti blinding systems | Rubber balls Slider rings Ultrasonic converters Combinations |

| Model sizes | 500 mm x 2000 mm 500 mm x 2500 mm 500 mm x 3000 mm 1000 mm x 2000 mm 1000 mm x 2500 mm 1000 mm x 3000 mm |

| Power | 3 phase, 380 V, 50 Hz or Customized |

| Motor | 2 x (0.4 kw – 1.5 kw) |

| Construction Materials | SUS 304 or Carbon Steel |

NCF series centrifugal screen.

The NCF series centrifugal screen is an equipment designed and produced by Navigat to solve screening problems such as materials that are light, easy to agglomerate, have low melting points, easily generate static electricity, and adhere to the back of the screen after passing through the screen, causing mesh clogging. It uses airflow to drive particles Separation, combined with ultrasonic system, solves problems such as screen clogging and low netting rate.

Dry particles, slurry materials

| Field of the application | Food,medicine,chemicals,abrasives,ceramics, mining, metallurgy,cosmetics and other industries |

| Feed size | 0.074 – 10 mm |

| Screen | Stainless steel 304/316 |

| Angle of inclination | 1°- 7° |

| No. of screen decks | 1 -2 per machine |

| Anti blinding systems | Rubber balls Slider rings Ultrasonic converters Combinations |

| Model sizes | 500 mm x 2000 mm 500 mm x 2500 mm 500 mm x 3000 mm 1000 mm x 2000 mm 1000 mm x 2500 mm 1000 mm x 3000 mm |

| Power | 3 phase, 380 V, 50 Hz or Customized |

| Motor | 2 x (0.4 kw – 1.5 kw) |

| Construction Materials | SUS 304 or Carbon Steel |

Compact sieve.

The vibration motor uses two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of its shaft to convert the rotational motion of the vibration motor into a multi-overlapping force of horizontal, vertical, tilt and centrifugal effects, and then transfers this force to the screen surface. So as to achieve the purpose of screening. Changing the phase angle and weight of the upper and lower eccentric blocks can change the size of the excitation force and the movement trajectory of the material.

Chemical industry

food

medicine

Daily chemicals

| Size Available | Dia.600/800/1000/1200/1500mm |

| Particle feed sizes: | 1 micron up to 20 mm |

| Feed rates: | 1kg/h – 10 t/h depending on machine size |

| Bulk densities: | 200 – 10000 grams/litre |

| Mesh openings: | 20 microns to 20 mm |

| No. of screen decks: | 1 – 2 per machine |

| Speed range: | 2860 (1500/3000)/min 50(60)Hz |

| Screen movement: | Three dimensional, set to product |

| Materials: | Stainless steel 304/316 |

| Areas of application: | For lower feed rates and simpler control screening operations; Fractionating of dry, powdered and granular products, and liquid-solid separation; Particularly well suited for heavy products and wet screening. |

Vacuum conveying.

Powder vacuum loading machine is mainly used to transport powder and granular materials, such as API powder, chemical powder, metal oxide powder, explosive powder; capsules, tablets, pills, small food particles, explosive particles, etc.; Suitable for conveying materials that are too wet, sticky, and too heavy.

Chemical industry

food

medicine

Metal

| Conveying capacity: | 0-6000KG/H |

| Conveying distance: | horizontal: 100 meters; Vertical: 25 meters |

| Equipment material: | 304/316L |

| Power: | 10W |

| Air pressure: | 0.6MPa |

| Gas volume: | 0.8m ³/ Min |

| weight | 20-60kg |

| Air consumption m3/min | 0.6-3.0 |

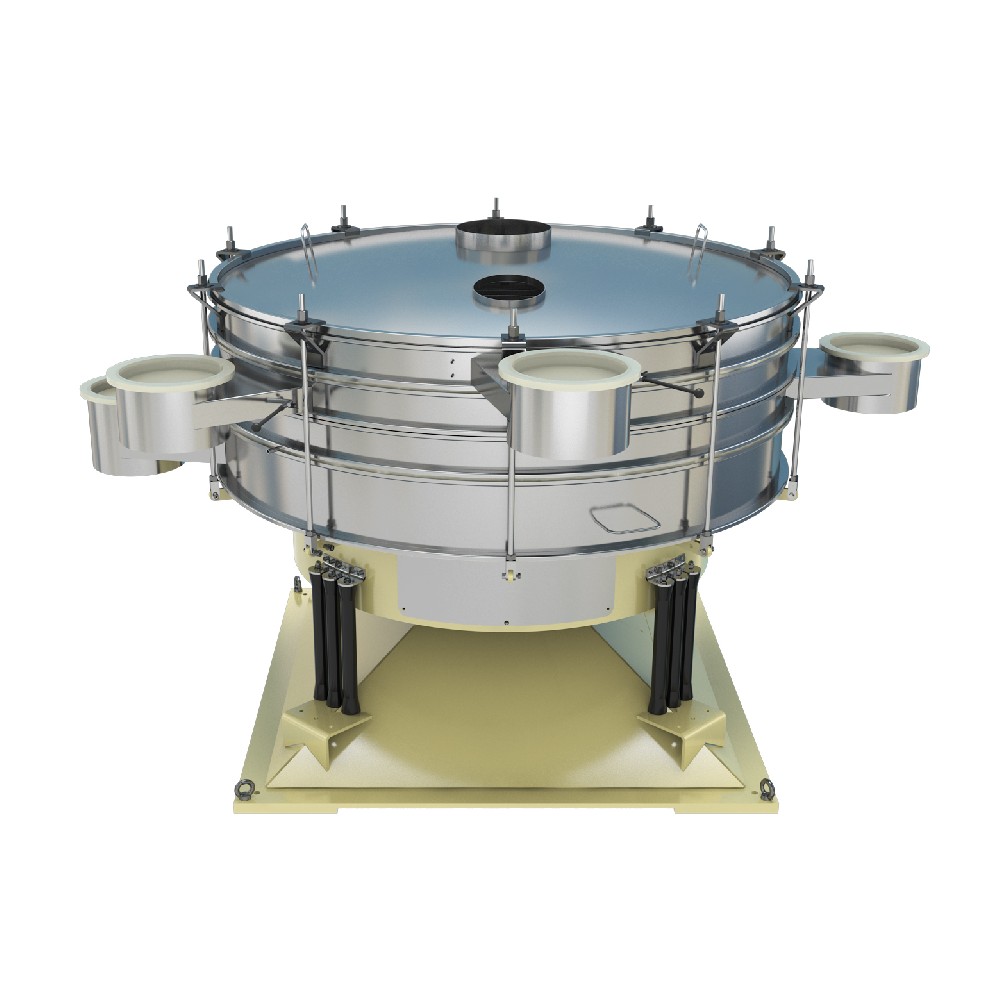

Tumbler screen.

Simulate manual screening motion, by adjusting the eccentricity, radial direction and cutting angle, the circular motion of the screen is combined with the upward parabolic motion to create a horizontal and throwing three-dimensional tumbling motion, and the materials are evenly dispersed across the entire screen surface from the center to the outer edge. , propagating in the axial direction with a spiral motion, thereby completing the screening process of fine particles.

Chemical industry

food

medicine

Metal

| Feed Sizes | 20 μm – 20 mm |

| Feed Rates | 1 kg/h – 50.000 kg/h |

| Bulk Densities | 20 – 10.000 g/l |

| Mesh Openings | 20 μm – 20 mm |

| Screens Usable | Stainless steel wire or perforated plates |

| No. of Decks | 1 – 5 |

| Mesh Cleaning | Jumping balls/rings, Rotating brush, Ultrasound |

| Speed Range | 180 – 280 min–1 |

| Screen Movement | 3-dimensional, settable |

| Acceleration | 1.3 – 1.8 g / 60 – 80 mm horizontal & 5 – 40 mm vertical |

| Materials | Carbon steel, stainless steels 304/316 |

| Machine Surface Treatment | Painted, brushed or mirror polished |

| Motor power (kW) | 1.1-4KW |

| Weight (kg): | 930-1750 |

High-efficiency fine powder vibrating screen.

small particle sieve

Chemical industry

food

medicine

Metal

| Applicable industries | Lithium battery, new energy, positive electrode materials, negative electrode materials |

| Production: | 1200KG/H |

| Number of sieve mesh | 200-600 |

| Network cleaning method | ultrasonic |

| Spray type: | ETFE/ECTFE 0.5MM thick |

| Screen surface diameter | 1000mm 1200mm 1500mm |

Dust-free explosion-proof feeding station.

The dust-free and explosion-proof feeding station is suitable for unpacking and feeding bagged and barreled materials in various industries. It can well solve the problem of dust flying during feeding. This product is a high-performance equipment designed in conjunction with the specifications and standards of FDA, GMP, and CGMP. The feeding station is ergonomic, which can greatly alleviate the fatigue caused by personnel during high-intensity feeding production. It is mostly used in pharmaceutical, food, chemical, health care products, energy, and other industries.

Chemical industry

food

medicine

Metal

| Operating interface wind speed | Not less than 0.3m/s, |

| Negative pressure air volume 1100m ³/ H | No dust overflow |

| Filter area approximately: | 9 * 0.2=1.8 ㎡ |

| Machine material: | 304 stainless steel |

| Mirror polishing of inner wall | Ra ≤ 0.4um |

| Applicable to: | Powder, particles |

Ton bag measuring and packaging.

The powder ton bag packaging machine is a large weighing packaging equipment. The powder ton bag packaging machine is specially designed for packaging powdery materials in ton bags. It is used to solve the problem of packaging fine powder materials in large quantities (more than 500 kg) such as grain, chemicals, feed, building materials, and minerals.

Chemical industry

food

medicine

Metal

| Applicable materials: | Starch, coal powder, pigment powder, pectin powder, fish meal, feed additives, etc. |

| Packaging weight: | 500KG |

| Feeding gear | Third gear |

| Completion process: | Feeding, weighing, bagging, and discharging |

NLB series inspection sieve.

engineers carefully designed the use of electromagnetic vibration instead of electric motors, and increased the kinetic energy of the screen, which can separate 625-mesh powder samples. The range of the standard inspection sieve body has been extended from 200mm to 75mm and 300mm sieve bodies, which are more suitable for processing The laboratory handles particularly complex or difficult materials.

Chemical industry

food

medicine

Metal

| Industries: | in all industries for dry, powdered and granular products |

| Particle feed sizes: | 2 micron up to 4 mm |

| Feed rates: | 10-500 grams |

| Bulk densities: | 20 – 10000 grams/litre |

| Mesh openings: | > 50 micron |

| Housing: | Metal |

| No. of screens: | 8×50 mm high or 16×25 mm high |

| Screen movement: | tridimensional |

| Screen receiver: | Metal |

| Timer: | > 0-99 min adjustable |

| Dimensions: | 360 × 790 mm |

| Weight: | 40 kgs |

| Electr. Power: | 230 V, 50/60 Hz, 0,019 kW, 12 A, |

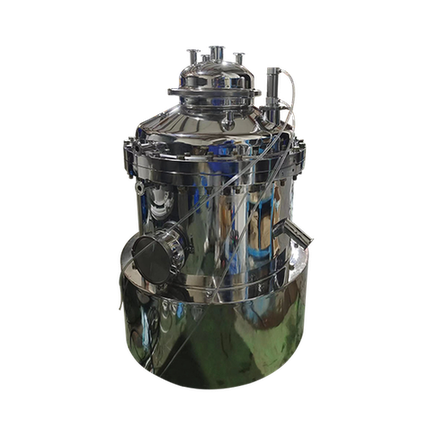

Microbead sterile separator.

The testing machine is in a sterile environment, with a single dose of 1.2L (different effects depending on pharmaceutical materials). Different models meet the test requirements and can be reproduced for large-scale production. The replica-scale production filtration and drying machine can handle up to 25L/batch of materials, and can be separated and dried in continuous batch operation mode to meet different process requirements. The ultrasonic function evenly distributes the product on the filter, and the drying speed reduces the formation of agglomerates.

Biopharmaceutical

| Material of the entire machine | The whole machine is 316L, electrolytic polishing is better than Ra<0.4 |

| explosion-proof | Explosion-proof motor |

| Customized control | PLC |

| Filtering situation | Two-layer, three-layer and five-layer filters (filters imported from Japan) |

| Vacuum degree | 0.2MPa |

| Sterility situation | Fully sealed design to meet sterility requirements |

| can be realized | CIP/SIP |

Laboratory negative pressure air flow screen.

The vacuum cleaner is connected to the sifter, causing a negative pressure in the inner cavity of the sieve. The air at the nozzle forms a strong airflow due to the pressure difference. The airflow is sprayed into the screen surface and then sucked into the screen hole. Therefore, samples smaller than the pore size are drawn into a vacuum cleaner or cyclone with the air flow through the pore size. The airflow helps disperse particles and purge the screen.

Chemical industry

food

medicine

Metal

| Available particle size range | 3 µ m~4mm |

| Maximum negative band | 100g |

| Maximum level | 1 (level 2 requires a cyclone collector) |

| Nozzle speed | 5-55 rpm |

| Time setting | 0-99 minutes |

| Extraction equipment | 2000-9999pa/20-99mbar/0.3-1.45psl |

| Can store parameter combination | 9+quick start |

| Available analysis sieve diameter | φ 200/ φ203 |

| Sieve tower height | 25/50mm |

| Size | 460 * 288 * 305mm |

NHI series vibrating screen.

Navector has accumulated enough experience in fine screening of various powders and UCS ultrasonic high-energy screening machines to design and manufacture other ultrasonic high-energy screening machines that cannot achieve the purpose and can separate in micron units. .

Chemical industry

food

medicine

Metal

| Type | 400 600 800 1000 1200 1500 |

| Power(KW) | 0.2 0.35 0.6 1.1 1.1 1.5 |

| Excitation Force(KN) | 4 7 13 20 20 32 |

High viscosity slurry filter.

The NHCF series silver paste filter screen equipment is based on the basic design principle of Germany’s precious and high-viscosity coating filtration technology, optimized design, and loaded with an ultrasonic system to achieve a filtering fineness of -8 μm even when the solid content is extremely high under normal pressure. The transducer is external, does not pollute the material, and is not affected by temperature. The scraper runs smoothly without damaging the separation network.

Chemical industry

food

medicine

Metal

| Equipment dimensions: | height 1500mm, width 500mm, depth 600mm |

| Weight: | 80kg |

| Working power supply: | AC220 ± 20% V 50Hz |

| Rated power of the host: | 600w |

| Main motor power: | 250w, speed 0-175r/min |

| Power of lifting motor: | 25w, up and down speed 20mm/s |

| Ultrasonic frequency: | 30kHz, 50w |

| Processing capacity: | 10-30kg/h |

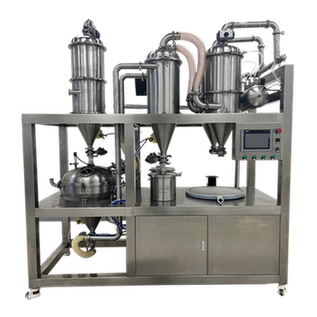

600 negative pressure air flow screen.

Easily sieve 1 micron micron powder and use 2000 mesh woven mesh as the medium for production and application.

Chemical industry

food

medicine

Metal

| Power supply: | 380 ± 10% AC 50Hz |

| Compressed air: | 0.4~0.6MPa oil-free, anhydrous, clean compressed air |

| Environmental temperature: | normal temperature |

| Environmental humidity: | Relative humidity below 65% |

| Explosion proof requirements: | NO |

| Product: | Powder |

| Equipment noise: | Less than 70dB beyond 1 meter |

NMS series butterfly screen.

The NMS series butterfly screen is a screening equipment developed and designed based on customers’ accurate demands for online spray powder recovery and online polishing fluid filtration circulation. Navigate can solve screening problems in production according to user needs.

Chemical industry

food

medicine

Metal

| Number of sieve mesh | 5-625 |

| Network cleaning method | ultrasonic |

| Network switching method | Grid fixation |

| Feed particle size | Maximum 5mm |

| Motor voltage | 220V 380V |

| Support customization | YES |

| Materials: | Stainless steel 304/316 |